Terracotta Panel

Aesthetically attractive,Sustainable & Energy Efficient

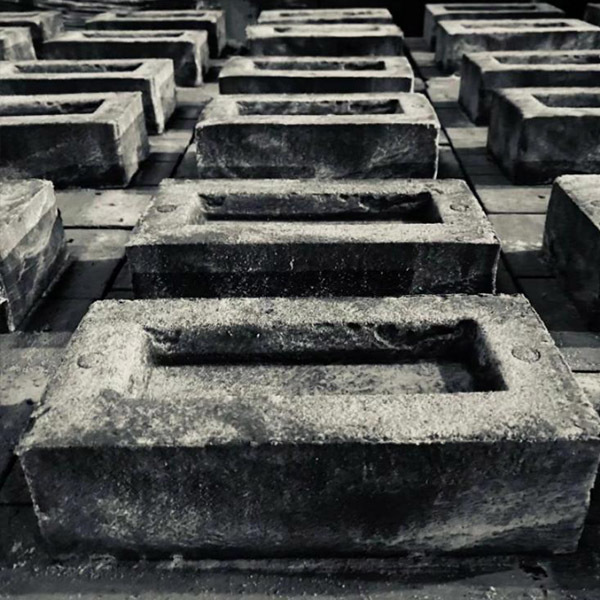

Terracotta panel is a type of architectural cladding made from fired clay. It’s used in facades to provide both aesthetic appeal and durability. Terracotta panels are lightweight, weather-resistant, and customizable, allowing for a range of textures, colors, and shapes. They are often used for their natural, earthy appearance and can be both functional and decorative in modern architecture.

MORE+SHAPING FACADES WITH CUSTOMIZED ART

As the president of Facade Master, I am deeply committed to shaping the future of architecture with every project we undertake. We don't just create facades—we craft works of art that transform buildings into lasting legacies. Our passion for ceramic and terracotta solutions fuels our relentless pursuit of excellence and innovation. Each custom design is a testament to our dedication to beauty, precision, and personalization. At Facade Master, we believe that every facade should be a masterpiece, reflecting the vision and spirit of those who build it.

- President,CEO of FacadeMaster - Yun Lee

INDUSTRY EXPERIENCE

DIVERSE PRODUCTS

CUSTOMER SERVICE

PROJECT REFERENCE

The Ningbo City Planning & Exhibition Center

Architect:Playze & Schmidhuber

Consultant:RFR

Place:Ningbo, China

Time:2016

Color:Green Glazed

Product:Customized Shaped Terracotta Panel

Qty:14400pcs

The Ceramic Pavilion

Location: Shanghai, China.

Architect: Zengqun, Temp Architects

Completion:2013

Products: Architectural Terracotta Cast

Color: Green Variable Glazed

Product Size: 515 *430*140mm

Qty: 1200pc

AESTHETICALLY ATTRACTIVE,SUSTAINABLE & ENERGY EFFICIENT, SAFE & STABLE.

FACADEMASTER offers a wide variety of colors, Textures, sizes, profiles, material properties, and installation options to meet the individual needs of architects and Clients. Its products are widely recognized for their safety, reliability, and energy efficiency in many completed applications worldwide.